By systematizing the entire supply chain management (SCM) plan, including demand forecasting, sales planning, medium- to long-term supply planning, Available-to-Promise (ATP) delivery date answers, and short-term production planning, manual labor is minimized, and information can be accessed quickly and accurately.

The system also incorporates specific requirements for polymer manufacturing, such as implementing a safety inventory policy that takes into account the monthly production cycle and formulating a supply plan based on the Production Wheel. This ensures that the system is tailored to the specific needs of the polymer manufacturing industry.

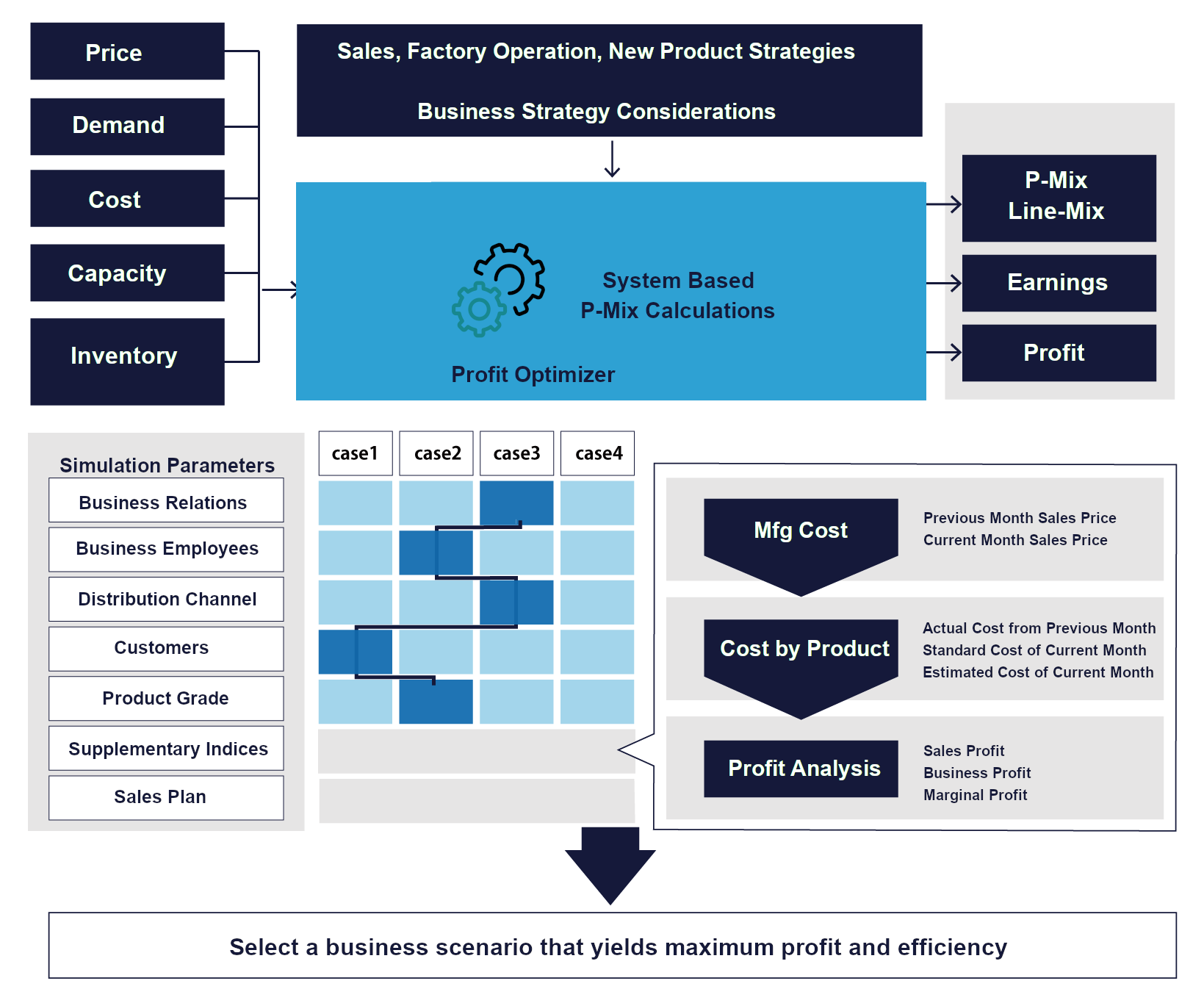

Adopting a company-wide unified system allows for all Production-Sales-Inventory (PSI) simulations to be performed and establishes a system for rational decision-making of supply and demand. This leads to the maximization of profits by ensuring that the company is always operating at optimal efficiency.