GA Release 2024

SaaS based Supply Chain Planning

Real-time DX for supply planning and inventory optimization

AI driven planning for Manufacturing, EC, SPA, and Retail Companies

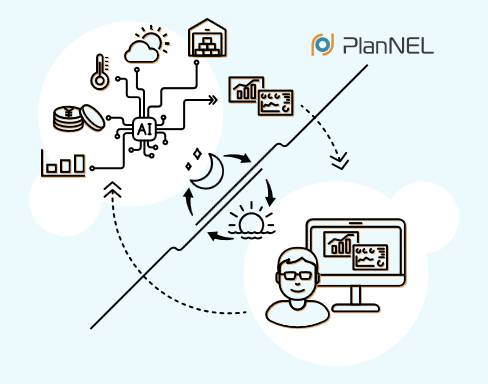

Planning Automation

PlanNEL is a comprehensive supply chain planning and inventory optimization platform that leverages data science and AI ML algorithms to create optimal plans for corporations. It addresses supply chain imbalances and fosters consensus among organizations through data sharing and smooth communication, ensuring a balanced and efficient supply chain.

Are you facing these supply chain challenges?

Ineffective demand forecasting

We previously relied on past experience to create material purchase orders, resulting in inaccurate demand quantities. This makes it difficult to validate sales plans proposed by our sales team.

Excess inventory and stock shortages

We struggle to understand variations in demand, leading to excess inventory. Additionally, sales promotions are not always accurately reflected in demand forecasting, resulting in stock shortages.

Planning process is time-consuming

We currently combine multiple data sources manually to plan order quantities. This process is time-consuming and does not improve plan accuracy.

PlanNEL can effectively address these supply chain planning challenges.

Achieve forecasting accuracy above 80%

PlanNEL utilizes AI and statistical techniques to create demand forecasts that consider not only variations in demand but also external factors such as weather and exchange rates.

Reduce planning cycle time by 80% or more

On a Cloud-based system, PlanNEL centrally manages demand forecasts and replenishment plans for multiple locations, taking into account planning policies and interdependencies within the entire supply network.

Lower excess inventory and stock-outs by 30%

By utilizing the latest data science technology, PlanNEL automatically simulates safety stock, cycle stock, order point, and order quantities by analyzing actual sales and inventory data.

PlanNEL's Strengths

Support from seasoned SCM experts

PlanNEL offers support for standard supply chain management (SCM) procedures that can be applied across various industry sectors, through the guidance of SCM consultants with over 10 years of experience.

SCM solution draws on over 20 years of expertise

PlanNEL is a service that is rich in in-depth industry experience accumulated over 20 years.

Advanced planning processes that ERP cannot handle

PlanNEL specializes in delivering advanced planning processes as the foundation of supply chain management, which in turn supports the execution of ERP.

Speedy system deployment with minimal setup cost

Because each module in PlanNEL is dedicated to a specific planning function, select and deploy only the modules required for your business needs.

Unlock your production potential with factory capacity planning

Unlock new heights of production with our expandable factory capacity planning system.

Please contact us for more information about PlanNEL

Leading companies such as Samsung, LG, and Brother Industries have successfully implemented Zionex's advanced technology and expertise.

Award History

Publications

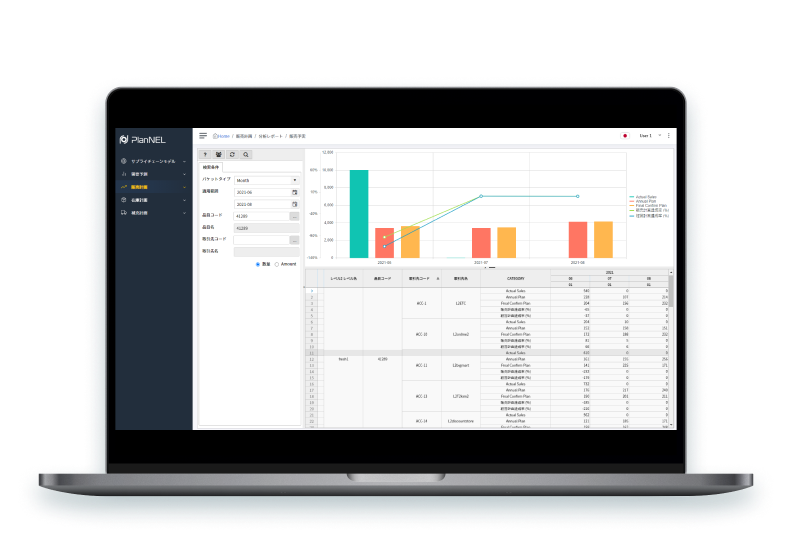

PlanNEL Modules

PlanNEL is an AI-powered platform that offers automated planning capabilities to help companies manage their supply chain and inventory efficiently. The 4 key modules include Baseline Forecasting (BF), Demand Planning (DP), Inventory Optimization (IO), and Replenishment Planning (RP). These modules are designed to work together to provide a comprehensive solution for managing a company's supply chain and inventory effectively.

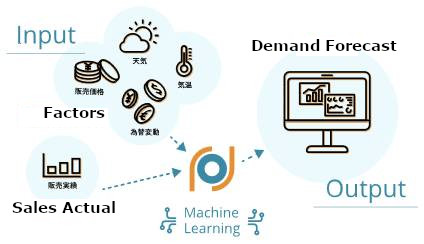

Baseline Forecast (BF)

BF module utilizes machine learning algorithms to analyze actual sales and demand influencing factors in order to make accurate forecasts. In conjunction with traditional statistical methods, PlanNEL provides powerful forecasting capability to match customer's future demand.

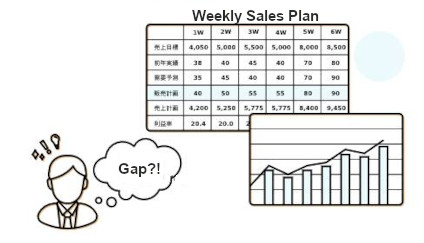

Demand Plan (DP)

DP module enables human input to improve and provide even more accurate predictions for strategic and priority items. This allows for real-time adjustments to sales plans by evaluating the gap between budget and profit, ensuring that sales goals are met effectively.

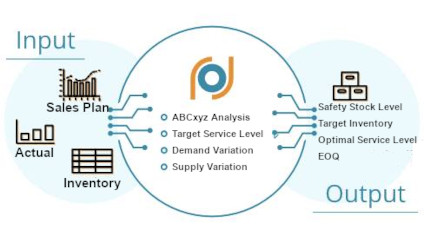

Inventory Optimization (IO)

IO module performs ABC-xyz analysis to maintain a desired service level for active sales items. This allows PlanNEL to provide inventory management guidelines, such as economic ordering quantity and safety stock, ensuring that inventory is managed efficiently and effectively.

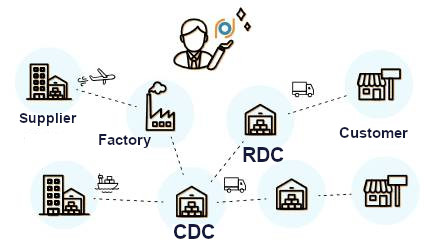

Replenishment Plan (RP)

RP module uses machine learning algorithms to calculate an optimal inventory replenishment plan for multiple inventory locations. This allows PlanNEL to meet demands on-time while minimizing excess inventory and ensuring efficient inventory management.

Benefits of using PlanNEL

FAQ

Association for Supply Chain Management (ASCM) sets international standards for supply chain management practices and processes for various industries. These standards are widely adopted as best practices by global corporations. PlanNEL, as a leading AI-based supply chain platform, also follows the SCM practices and processes defined by ASCM to ensure optimal performance and compliance.