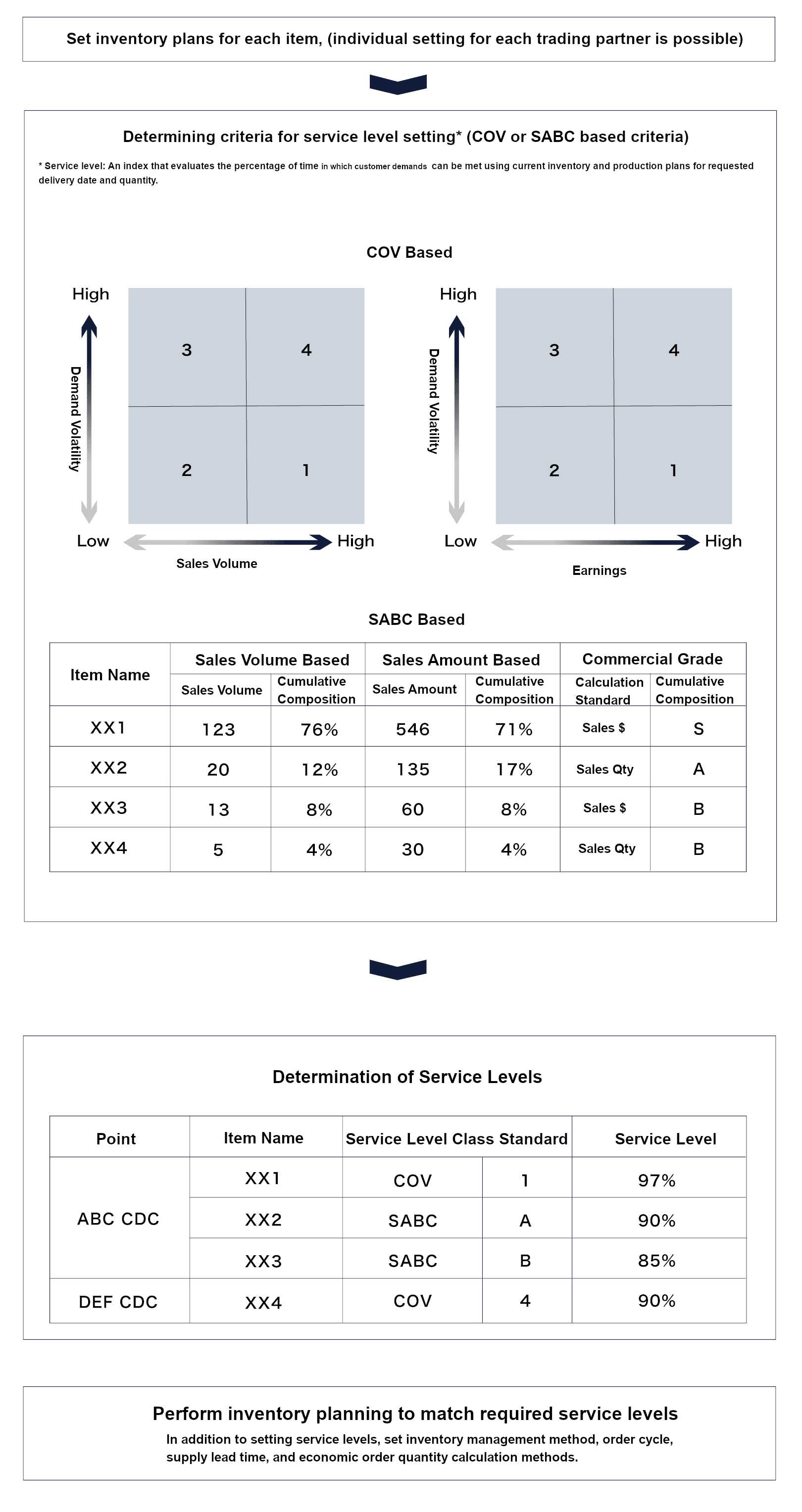

By implementing a replenishment plan and inventory management plan based on the rules for each product group and the demand plan for each product, Company A is now able to effectively prevent out-of-stocks and excess inventory. This approach allows the company to optimize inventory levels and maximize profits without losing potential sales opportunities.

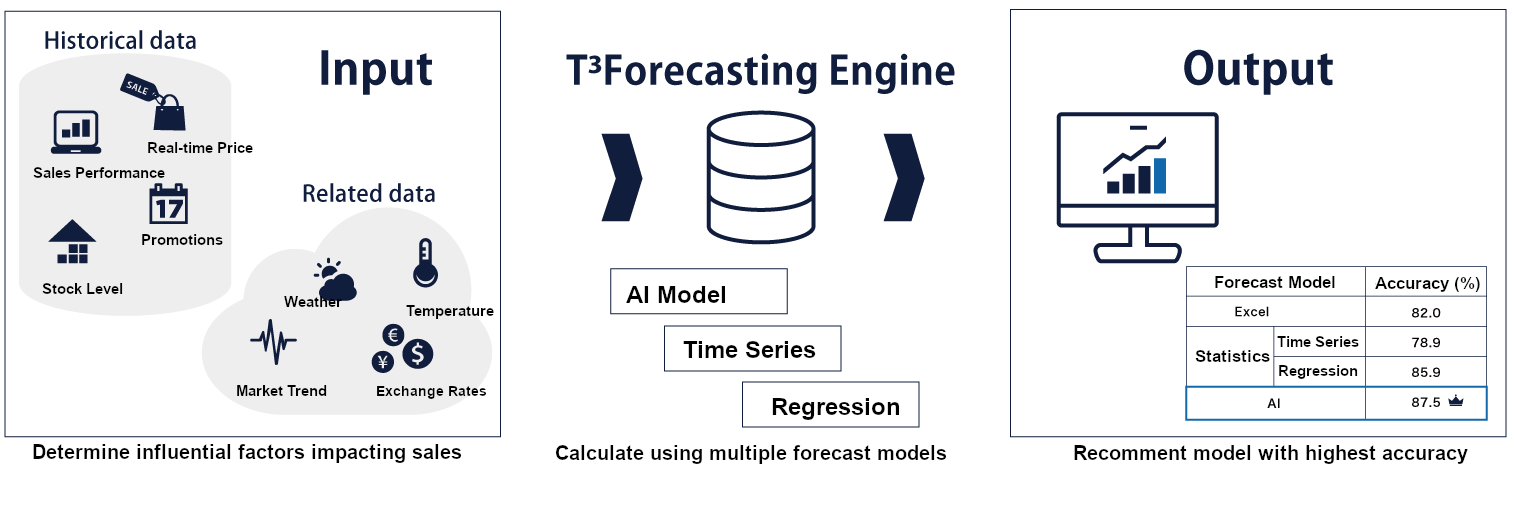

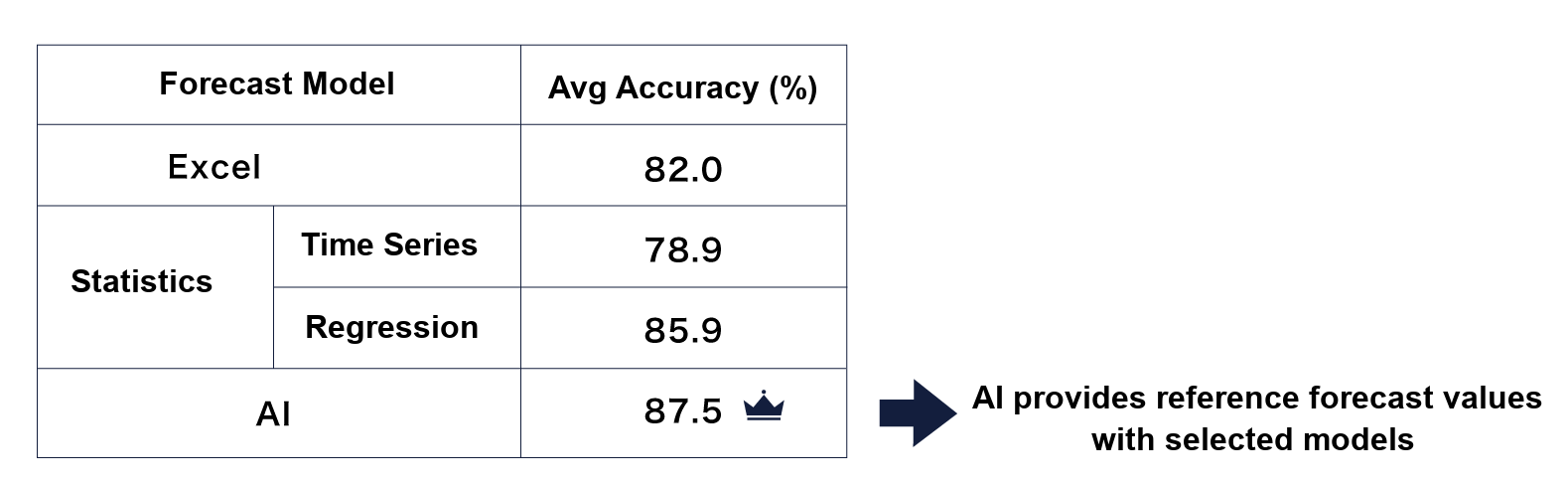

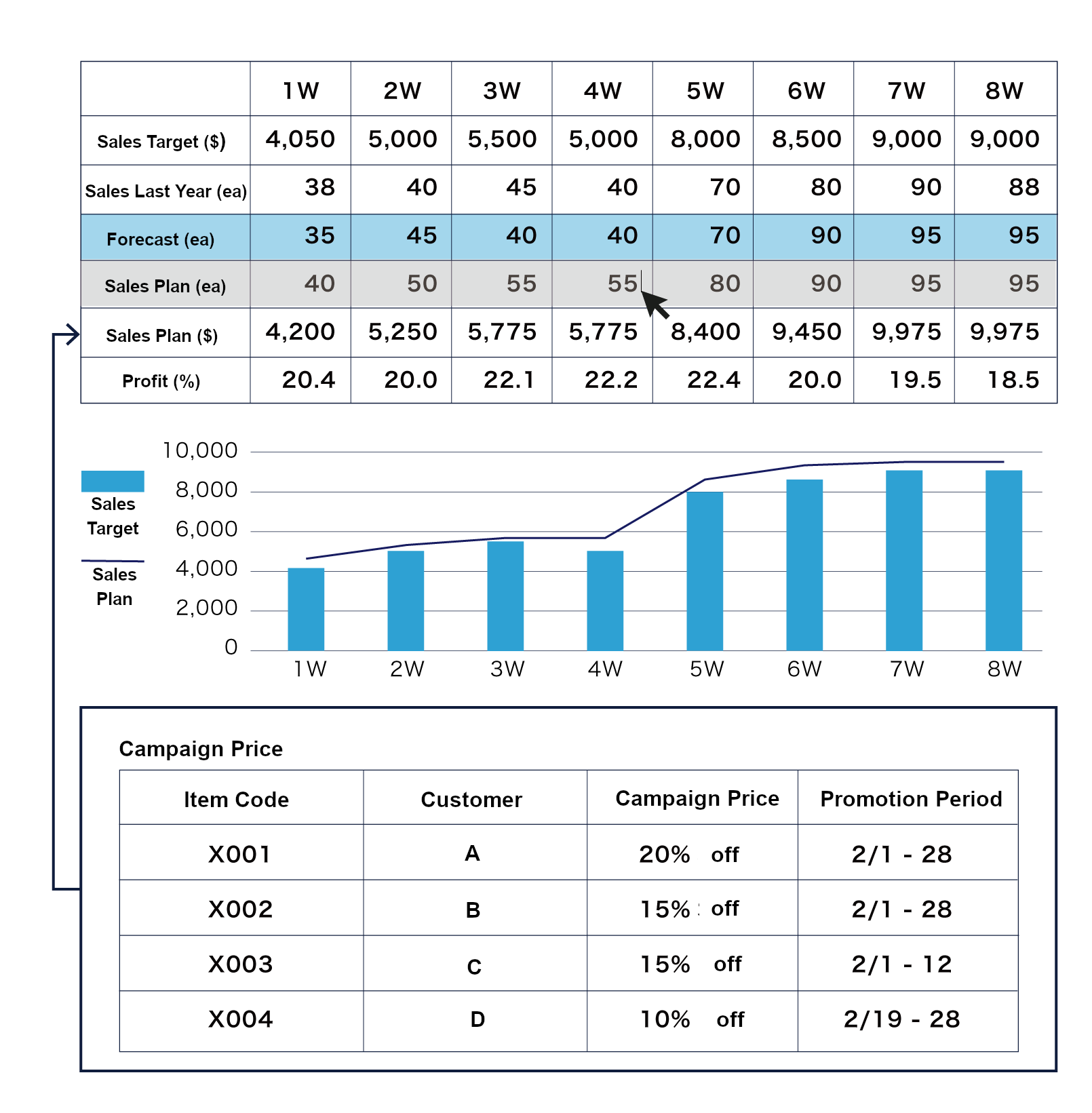

Automating demand forecasting has enabled the company to more quickly and accurately manage inventory calculations by item and business partner, replacing the previous Excel method. This, in turn, allows the company to formulate a realistic production plan for each factory, taking into account all constraints such as setup changes, available inventory, and resource capacity.

Furthermore, the company can now handle manual changes caused by urgent orders from promotional events more efficiently, ensuring that inventory and production can be adjusted in a timely and effective manner.