High Tech Industries

Overview

Brother Industries implements supply chain planning capabilities, streamlining its demand planning processes

Brother Industries, Ltd., a global leader in technology and manufacturing, implemented supply chain planning capabilities with Zionex, enhancing its demand planning processes. Brother has a rich history dating back to 1908 when it began as a small repair shop for sewing machines in Nagoya City, Aichi Prefecture. Today, the company has evolved into a multifaceted manufacturer, producing and selling a wide range of products including printers, multifunction devices, sewing machines, and industrial equipment. With production bases, sales, and service centers spanning over 40 countries and regions worldwide, Brother Industries is able to provide its customers with high-quality products and services on a global scale. The company's printing equipment and sewing machines have become synonymous with quality, reliability, and innovative design, earning them a strong reputation and brand power worldwide.

Project Background & Goals

Brother Industries has been expanding its business operations in recent years, leading to an increased demand for efficient and effective business management systems. The company's European and American branches have implemented ERP systems to manage their operations, however, the Asian branches continue to rely on Excel for sales planning and ordering. This has resulted in difficulties in obtaining a comprehensive global sales plan and forecasting inventory levels at the head office. Additionally, the increasing number of business bases and products has made it challenging for Asian sales companies to accurately plan for production and inventory. To address these issues, Brother Industries has implemented a system to visualize monetary information on a global scale, as well as a demand planning system that can respond quickly and effectively to changes, which is not dependent on the individual planner's competence.

Project Approach

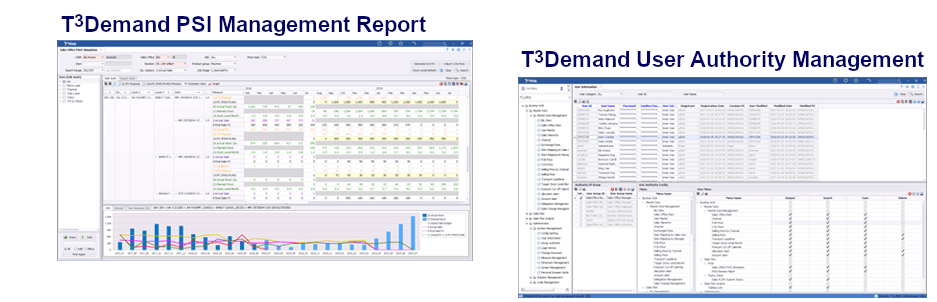

As a first step towards achieving our goal of improving global sales coordination and inventory management, we implemented a system that seamlessly integrates our ERP system with our conventional sales plans. This allows for comprehensive and real-time analysis of key performance indicators such as sales status, production schedule adherence, and inventory levels, both in terms of quantity and monetary value.

As a second step, we developed advanced sales planning and order planning capabilities specifically tailored for our major Asian sales companies. The system allows for easy switching between different levels of granularity, including major customers, sales companies, detailed items, and large categories, and enables the analysis of historical data and forecasting of future demand. This allows our Asian sales companies to more efficiently and accurately plan and manage their sales and inventory, while providing valuable insights to our head office for global coordination and decision making.

Return on Investments

In Phase 1 of this project, we implemented a comprehensive system that allows for the daily coordination of sales and inventory management through the use of ERP and traditional sales plans. This system also enables multifaceted and timely analysis of key performance indicators such as sales status, purchase sales inventory (PSI) and more, in terms of both quantity and value. This allows for the quick identification of global trends and the development of effective countermeasures.

In Phase 2, we built robust sales planning and order planning functions specifically tailored for major Asian sales companies. These functions allow for easy switching between different views such as major customers, sales companies, detailed items, large categories and quantity versus value, making it possible to analyze past performance and predict future demand. This improves the accuracy of PSI and allows for more efficient sharing of information and planning with relevant parties.

By expanding this approach to other Asian, European and American sales companies, we anticipate that Brother Industries will be able to effectively share its expertise in demand planning and strategy across the entire organization, resulting in improved performance and customer satisfaction.