Heavy Industries

Doosan Heavy Industries

Business Environment

Doosan Heavy Industries, a subsidiary of the South Korean Doosan Corporation, is a leading provider of heavy industrial equipment, including power generation equipment, plant equipment, and infrastructure equipment. With a strong focus on overseas operations, the company has a proven track record of delivering large-scale projects and power plants in countries such as Saudi Arabia and India, positioning itself as a reputable global EPC company.

Project Background & Goals

Doosan Heavy Industries is well-known for its expertise in building large plants and power plants overseas, such as in Saudi Arabia and India, and is considered a leading global EPC (Engineering, Procurement, and Construction) company. However, in order to maintain cost competitiveness and ensure quality, it is essential to improve operational efficiency.

Despite the company's success, there were challenges to business expansion due to decentralization of various engineering data, personalization of the design process, and lack of visibility into the design schedule. The process of expanding projects and complying with strict laws and regulations was also complicated and relied heavily on individual skills and ingenuity. These issues made it difficult for Doosan Heavy Industries to adapt to the PLM (Product Lifecycle Management) system that supports the conventional parts assembly method.

To address these challenges, the company decided to build a system using the SI (Systems Integration) development method based on the Aras Innovator platform. This platform guarantees scalability and flexibility, and will help the company anticipate future changes while ensuring efficient and streamlined operations. This new system will allow Doosan Heavy Industries to improve operational efficiency, maintain cost competitiveness, and ensure quality, while expanding projects and complying with strict laws and regulations.

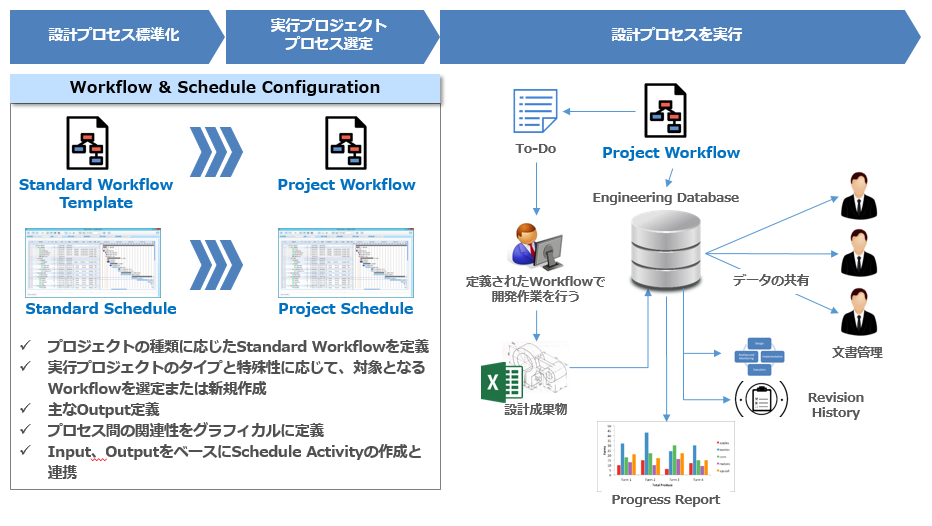

By implementing the Aras platform and utilizing its capabilities, Doosan Heavy Industries was able to streamline and standardize their design process, resulting in improved accuracy and efficiency. By utilizing the Dynamic Task Manager and Gantt charts for project scheduling, the company was able to better manage workflow tasks and share schedules with ease. Additionally, by utilizing an engineering database to systematically manage the specification information of equipment, the company was able to standardize the classification of equipment and import this information to create 3D modeling. This allowed for better management of equipment attributes and access rights, further improving the overall efficiency and effectiveness of the company's operations.

Return on Investments

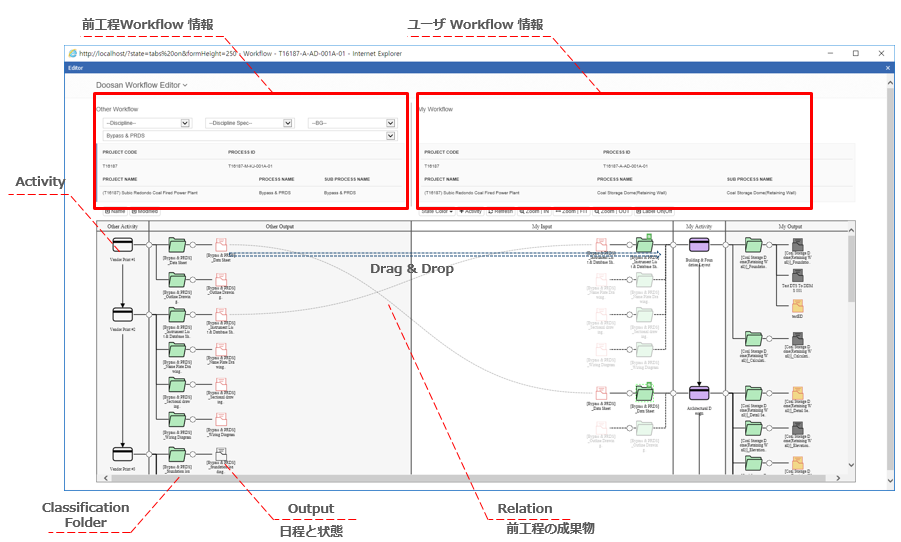

By implementing a standardized workflow and defining standard business processes, Doosan Heavy Industries was able to establish a comprehensive and integrated design environment. To ensure that the design process was executed according to the defined workflow, an easy-to-use editor was developed that associates activities and deliverables with a graphical management screen. This allowed all users to seamlessly navigate the design process and intuitively understand the relationship between business status and documents.

The introduction of an equipment library and engineering database allowed for systematic management of specification information, which enabled accurate calculation of material and equipment quantities through 3D modeling. This served as a valuable source of data for equipment procurement, construction, and production, as well as for estimation of similar projects. Additionally, the engineering portal allowed stakeholders to share updates in a timely manner, improving design integrity and allowing all parties to use the portal page for delivery/request procedures and data registration. The project status can be monitored on the dashboard, which is constantly updated with new information. The company is currently working on further collaboration with Supply Chain Management to support a wide range of projects.